When it comes to selecting a lamp, we do not just look at the functionality but the aesthetics and durability. In order to enhance the duration and design of the lamps, there are several surface treatments that can be considered according to budget and use. Understanding the difference can help the buyer to make the final decision. We will talk about some of these painting methods

Spray paint

As it named said, it use an aerosol paint or a paint gun to spray the paint into the surface. This method offers a variety of colors and finishing , it is easy and cost-effective making the most common method used.

Although this method is versatile and easy to apply, it is not recommend if you will handle the lamps often as the color may wear away, revealing the metal surface.

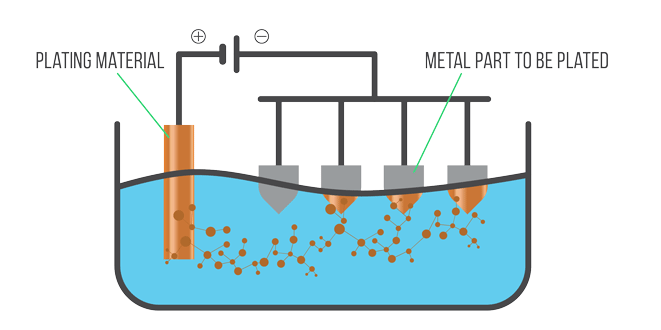

Electroplating

Electroplating uses electricity to give the object a protective and glossy layer. Basically it needs to deep the object into an special liquid and use the electrical current to stick a thin layer of metal (like gold, nickel or chrome) into the surface. This method can provide excellent corrosion resistance, improve aesthetic appeal, and increase surface hardness.

Lamps that are electroplated have a luxurious appearance, smooth and shiny surfaces. They are also more durable than spray painted, making it highly suitable for items that experience regular use. However its complex process make it more expensive than spray paint.

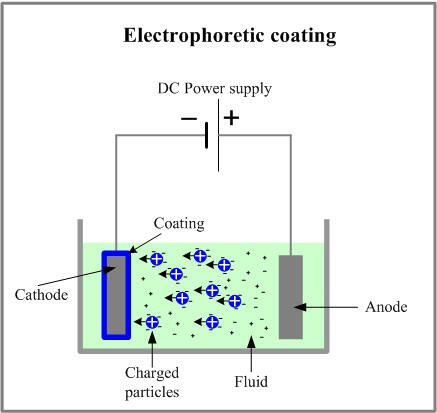

Electrophoresis

Also known as e-coating or electrodeposition is a method similar to electroplating, using electricity to apply the color onto the body, however this method is more environment friendly as it use a water soluble solution to immerse the metal body and deposit the coating onto the surface.

It provides a smooth and uniform coating, good anti-corrosion performance and high durability

Usually less expensive than electroplating and anodizing, providing affordable and durable items.

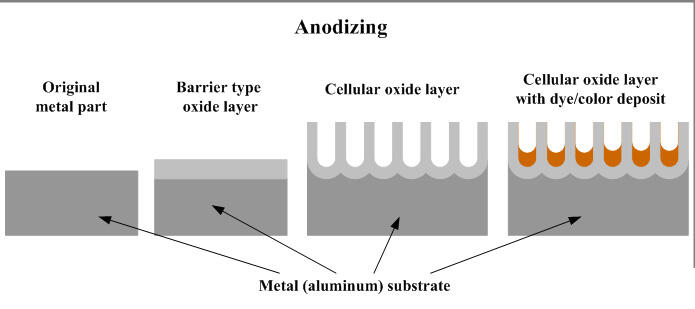

Anodizing

Anodizing is a process that increase the thickness of the natural oxidation layer of a metal providing a hard and resistant to corrosion surface that can be dyed in a wide range of colors. This process is more expensive as it takes more energy and requires expensive materials.

The lamps made with this process not only are stylish but also maintain their appearance over the long term, making it a top option for both indoor and outdoor use.

Conclusion

Jianbian Lighthing Technology is one of the top 10 manufacturers of cordless table lamp in China, we understand that choosing the right finish for your lamp its beyond aesthetics; we will help you to choose the best based on your preferences and needs, ensuring that the lamps of your choice will meet your requirements.